Transforming Industrial Operations: A Dive into Co-Bots

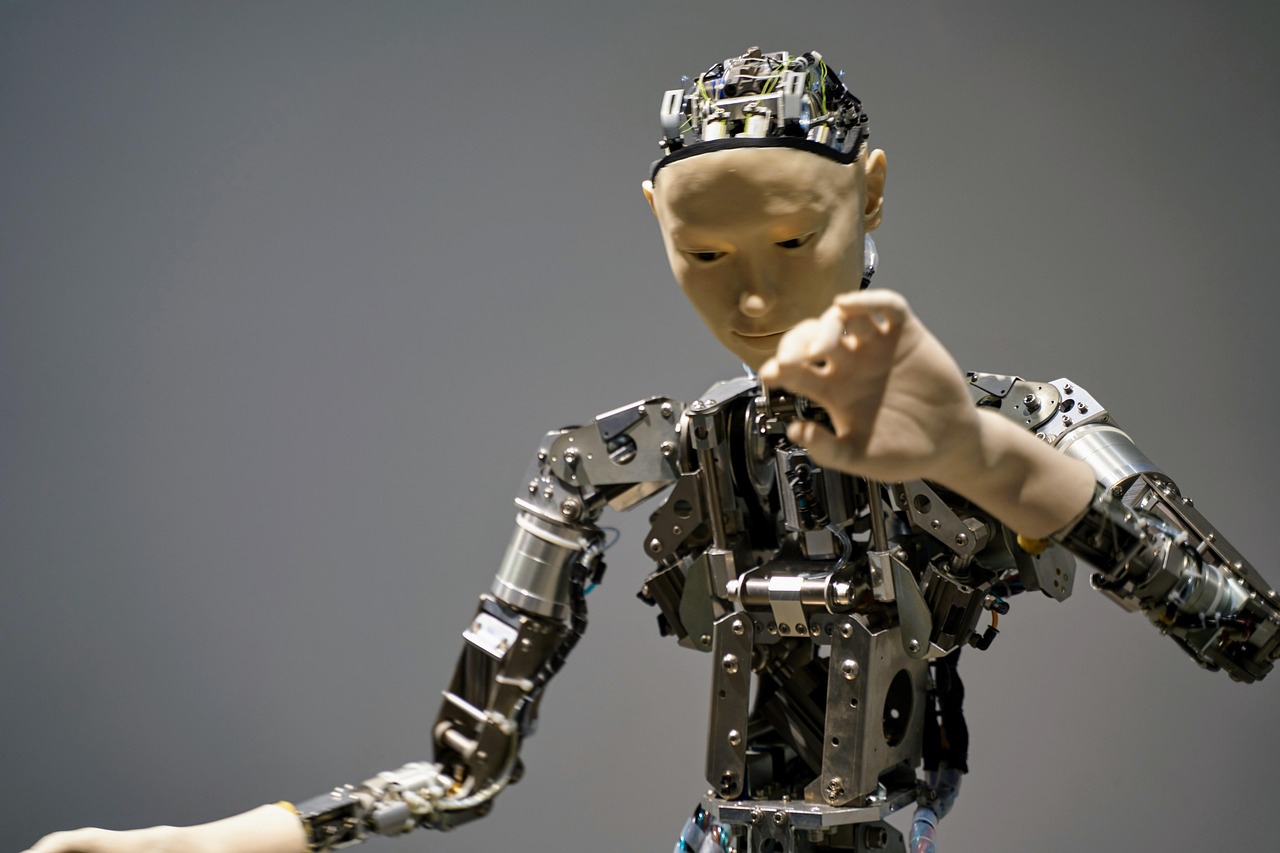

Introduction: Amidst an era of rapid technological change, a rising star is gaining traction within the industrial sector: collaborative robots, or 'co-bots.' This article explores the rise of co-bots, their contributions to the industry, and the challenges they pose.

Background and Development of Co-Bots

Collaborative robots were first introduced in the late 1990s as a safer, more flexible alternative to traditional industrial robots. Co-bots are designed to work alongside humans in shared workspaces, with their primary advantage being their ability to learn tasks from human operators. Over the years, advancements in sensor technology and artificial intelligence have further enhanced their capabilities and broadened their application range.

Current Trends and Insights

Today, co-bots are being leveraged by businesses across industries, from automotive manufacturing to pharmaceuticals. They are not only being used to automate routine tasks but are also being deployed for more complex operations that require human-like dexterity and precision.

Co-bots are uniquely positioned to address some of the biggest challenges in industrial operations today: labor shortages, productivity bottlenecks, and safety concerns. They can work round-the-clock without breaks, perform tasks with greater speed and accuracy, and reduce the risk of workplace injuries.

The Impact of Co-Bots in Industrial Operations

Despite their many benefits, the adoption of co-bots also brings challenges. The upfront investment can be significant, and there is often a need for staff training. Additionally, there are concerns about job displacement, with critics arguing that automation could lead to job losses.

However, many experts believe that co-bots will create more jobs than they displace by freeing up humans to focus on more complex, value-added tasks. Furthermore, the use of co-bots can lead to increased productivity and competitiveness, which could, in turn, drive business growth and job creation.

The Future of Co-Bots

Looking ahead, the co-bots market is poised for substantial growth. As technology continues to evolve, we can expect to see co-bots that are even more sophisticated, versatile, and user-friendly. Moreover, as businesses increasingly recognize the potential of co-bots, we are likely to see a more widespread adoption across industries.

Practical Insights for Co-Bots Integration

- Start with a clear understanding of your operational needs and challenges. This will help you identify the tasks that could be automated using co-bots.

- Consider the human factor. Successful co-bot integration requires acceptance and cooperation from the workforce. This can be facilitated through proper communication and training.

- Plan for the long-term. While the upfront costs of co-bot adoption can be high, the potential productivity gains and cost savings can make it a worthwhile investment in the long run.

In summary, co-bots represent a transformative force in industrial operations. By working alongside humans, co-bots can enhance productivity, improve safety, and help address labor shortages. While there are challenges to their adoption, the potential benefits make them a compelling option for businesses seeking to optimize their operations. As we move into the future, co-bots will undoubtedly play an increasingly significant role in shaping the industrial landscape.